Every year I move into a new room on campus at Georgia Tech, I buy a package of sticky putty, hoping that it will be strong enough to hold my large posters of the periodic table and Chance the Rapper, because command strips are just way too expensive. They usually fall down in the middle of the night, waking me up in terror. Recently in my polymers class, I learned about the beauty of spider silks and how they secrete different silks to accomplish different tasks. When I googled “spider silk,” I found articles and youtube videos claiming that spider silk is stronger than steel. I wondered how spiderwebs are able to stick to walls better than my command strips, but when I accidentally run into one, it breaks easily.

After doing some research, I learned that strands of spider silk are actually made of thousands of close-packed, parallel nanostrands, and depending on the gland they are secreted from, their tensile strength is 100-400 kpsi, compared to steel, which is 40 kpsi [1]. The secret is in how the tensile strength is measured. Tensile tests consist of putting a material in tension, essentially stretching it until it breaks. Spider silk is made of semi-crystalline polymer nano strands that can stretch a lot before breaking, and having many strands stacked together makes it even stronger, while steel thread of the same diameter or density has a crystalline structure that doesn’t stretch. This scenario is analogous to breaking a single stick of strong wood versus breaking a bundle of many weaker but stretchier sticks of wood: the bundle wins.

Spiders have different glands that secrete silks with different properties as protein structures to accomplish different tasks [2]. The tubuliform gland creates the silk to make the hard outer shell for an egg sac, and the aciniform gland makes the inner lining of the egg sac. The aggregate and flagelliform glands produce the sticky droplets and capture spiral threads, respectively, to catch prey. The major ampullate gland makes the frame of the web as well as the dragline silk that allows the spider to move around. Lastly, the pyriform silk gland is responsible for the silk that attaches the web to the walls, trees, your bedroom window, etc. Pyriform silk is described as a “protein glue” or a “glue-like cement” that holds small amino acid fibroins, which then connect larger dragline silks, and are sometimes reinforced by aciniform silk [3]. Together, all of these components create a very strong network of silks that makes the overall product very adhesive.

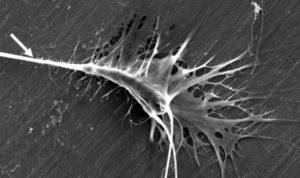

In this picture from a study that took Scanning Electron Microscope (SEM) images of a single attachment point of a web, it looks like the pyriform silk is a splat of glue with the dragline silk (white arrow) stuck in it [4]. Looking closer, the “glue” looks like a network with many, smaller attachments to the surface of the wall.

Meanwhile, the sticky putty that I use to try to hang up my posters isn’t as robust as the spider silk glue. The formula for sticky putty is a trade secret, but it is known that it works as a pressure-sensitive adhesive, so the extent of adhesion depends on the amount of pressure you apply to it, as well as the shape and geometry. So even though I add a lot of pressure to the poster when I first apply it, depending on the weight of the poster and the amount of putty I used, the poster will slowly pull the putty off the wall, depending on how much I used and the temperature of my room [5].

If spider silks are so strong and perform so many tasks well, why don’t we make adhesives or other high performance materials out of it? There have been many ideas for potential uses of spider silk in body armor due to its mechanical properties. It is also antimicrobial, so there are many ideas for biomedical applications, such as scaffolding for tissue generation [2]. However, spider silk is extremely difficult to harvest. This is because spiders are inherently cannibalistic and produce a small amount of silk in comparison to silk worms, which are typically used to harvest silk for textiles. Scientists have attempted to put spider genes in silkworms, but the silk they produce still isn’t of the same quality [6]. So unfortunately, I probably can’t get a spider as a pet and harvest the silk for my dorm posters. But doing all this research made me curious: How is Spiderman’s silk compared to actual spider’s silk? And where are the silk glands?

References:

[1]Hayashi, C. Y., Shipley, N. H., & Lewis, R. V. (1999). Hypotheses that correlate the sequence, structure, and mechanical properties of spider silk proteins. International journal of biological macromolecules, 24(2-3), 271-275.

[2] TED. (Dec 7, 2011). Hayashi, Cheryl: The Magnificence of Spider Silk [Video file]. Retrieved from https://www.youtube.com/watch?v=xossR6eHv3I&t=248s

[3]Hardy, John & Römer, Lin & Scheibel, Thomas. (2008). Polymeric materials based on silk proteins. Polymer. 49. 4309-4327. 10.1016/j.polymer.2008.08.006.

[4]Blasingame, Eric et al. “Pyriform spidroin 1, a novel member of the silk gene family that anchors dragline silk fibers in attachment discs of the black widow spider, Latrodectus hesperus.” The Journal of biological chemistry vol. 284,42 (2009): 29097-108. doi:10.1074/jbc.M109.021378

[5] “Blu Tack FAQs.” Blu Tack, Wayback Machine Internet Archive, 2010, web.archive.org/web/20100418062649/http://www.blutack.com/faq.htm.

[6] SciShow (Feb 4, 2019). Green, Hank: Why Can’t We Make Spider Silk? [Video file]. Retrieved from https://www.youtube.com/watch?v=UX2LHcLxjio