In my childhood, I always imagined the picture of me talking to myself. As I grow up, I first saw the introduction of 3-D printing on TV. 3-D printing makes me believe the possibility of creating another me.

3-D printing also called Additive Manufacturing(AM) refers to any process of printing 3-dimensional objects. Under the control of a computer, the raw material is piled on top of another.

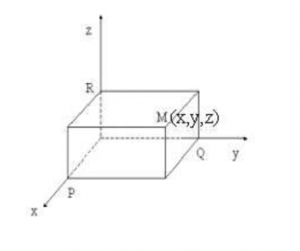

To better understand the principle of 3-D printing, let’s first focus on the traditional way of printing—2-D printing. Traditional printing works on the pictures on a plane. Digital pictures consist of pixel plots with pure colors. It can be seen as every coordinate plot stores one color. Transmission is completed by synchronous orbits.

Instead of paper and paintings, the raw material for 3-D printing is normally thermal plastic which turns soft when heated. Nowadays the most common material for 3-D printing is ABS. PLA is also called Polylactic Acid. It has a very low melting point of below 185 Celsius. Therefore, it is used broadly in 3-D printing. It appears as wire rod just like wool, so it is not easy to stuck the painter.

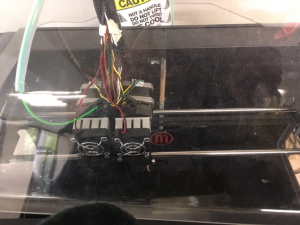

Now that we know the material of 3-D printing, let’s see how the printer works. For x-axis and y-axis, we use a small steel plate on synchronous orbits. For z-axis, we use a thick rod appearing like a screw. And that is the basic construction of a 3-D printer. It is not as complicated as I originally thought. Basically, we just need to make a sprinkler head that can move in a three axis. Then, use silk thread to create planes and pile up the planes into a three-dimensional object.

We only need a JPG formed picture to print a picture. However, what kind of form do we need to complete a 3-D printing? In industrial design and architecture, rhino and solid work are really popular software. Almost all software in the world have the same basic function—squeeze. The form of a model for 3-D printing is STL..

Now let’s discover the technology of 3-D printers.

- FDM(Fused Decomposition Modeling)

The key to FDM is to keep the temperature 1 Celsius above the melting point of the raw material. The sprinkler head is controlled by CAD tier data to make the raw material squeezed out and solidify as thin layers. The layers pile up to form a model.

| name | FDM |

| material | ABS,PC,PLA |

| precision | 0.025-0.762mm |

The principle of construction of the system and operation are very easy. Maintenance cost is low. System operates safely. It can be used in lost wax casting and forming parts of any complexity. It does not need chemical cleaning.

- SLA(Stereo Lithography Apparatus)

SLA uses photosensitive resin as raw material and scans UV laser controlled by a computer so that the scanned area of the resin layser has photopolymerization reaction and form a layer of the component. Through continuously bonding the previous layer, the whole object is created.

| name | SLA |

| material | Photosensitive resin |

| precision | 0.1-0.2mm |

This method has a high degree of molding process, a high precision of sizes and great quality. It uses CAD data model to lower the cost of repairing. It can work on objects with complicated structures.

- SLS(Selected Laser Sintering)

It uses CO2 laser as energy source and powder material as raw materials. First, put a thin layer of powder on the working table; Then, the laser beam is selectively sintered under the control of the computer according to the layered outline of the part. After the layer is completed, the next layer is sintered. Next, remove all excess powder after sintering, grind and dry the other treatments. Nowadays, wax, plastic powder and metal powder are broadly used.

| name | SLS |

| material | Nylon, ABS |

It can be used to make metal products with easy procedures. It does not need supporting structure. The utilization of material is high.

- Ployjet

Sliding back and forth along the x-axis, an ultrathin photosensitive resin is spread over the molding chamber. After each paving, the UV light bulb on the edge of the sprinkler head and immediately emits UV light to rapidly cure each layer of light-sensitive resin. After each print, the molded chassis inside the machine sinks, while the sprinkler head continues to work layer by layer until the prototype is completed.

| name | Ployjet |

| material | Photosensitive resin polymeric material |

| precision | 0.1mm |

It can print 3-D model with high quality, great details and shorten the designing period. The range of choosing material is broad.

(https://www.zhihu.com/question/20382142)

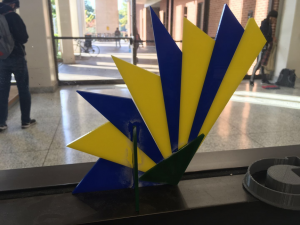

Nowadays, 3-D printing has got some breakthroughs in many areas. Cornell creating machine lab states that Hydrocolloid Printing’s 3-D printing can custom food production. It is possible to print candy, chocolate and pasta now. Industrial 3D printers have existed since the early 1980s and have widely used for research purposes. Fashion designers also use the 3D printed bikini swimmer, shoed and dresses for generating ideas. Nike took advantage of 3-D printing technology in the modeling and production of Vapor Laser designed for American Players in 2012. 3-D printing has also been used in production of transplant organs, equipment and other medical fields. There are currently successful cases of a titanium pelvis transplanted by a British patient and a titanium mandibular transplanted by a Belgian patient.

( https://zh.wikipedia.org/wiki.E5.B7.A5.E4.B8.9A.E7.94.A8.E9.80.94)

Resources:

3D Printing.J.Maslin-Research Assoc.Dec-1976

3D Printing: the Ultimate guide to understanding and mastering 3d printing for life.Greg Norton-Createspace Independent-2015